Life at RGE: Kaka Wong’s Journey of Growth and Grace

From a challenging start to a well-established role, Kaka has earned her position as a respected leader and colleague. A graduate of Hong Kong University, Kaka’s career began in banking,...

Latest updates on what's happening in RGE Group

To accelerate innovation in textile recycling, RGE jointly launched the RGE-NTU Sustainable Textile Research Centre (RGE-NTU SusTex) with the Nanyang Technological University Singapore (NTU) on 4 Aug 2022.

The S$6 million research centre marks Singapore’s first textile recycling initiative, with a clear aim of translating research outcomes into practical solutions that can be deployed in urban settings like Singapore. Researchers will develop new technologies to recycle textile waste into fibre and create new, next-generation eco-friendly and sustainable textiles.

The launch of RGE-NTU SusTex comes at a time when an estimated 90 million tonnes of textile waste is generated and disposed of every year, with less than 1% being upcycled. The textile industry is also responsible for 10% of global greenhouse gas emissions[1] – more than international flights and maritime shipping combined.

RGE Executive Director, Mr Perry Lim, said, “As the world’s largest viscose producer, we want to contribute where we can achieve the most impact. More countries are banning the import of waste, including textile waste. However, current textile recycling technologies, which rely on a bleaching and separation process using heavy chemicals, cannot be implemented in urban settings such as Singapore.”

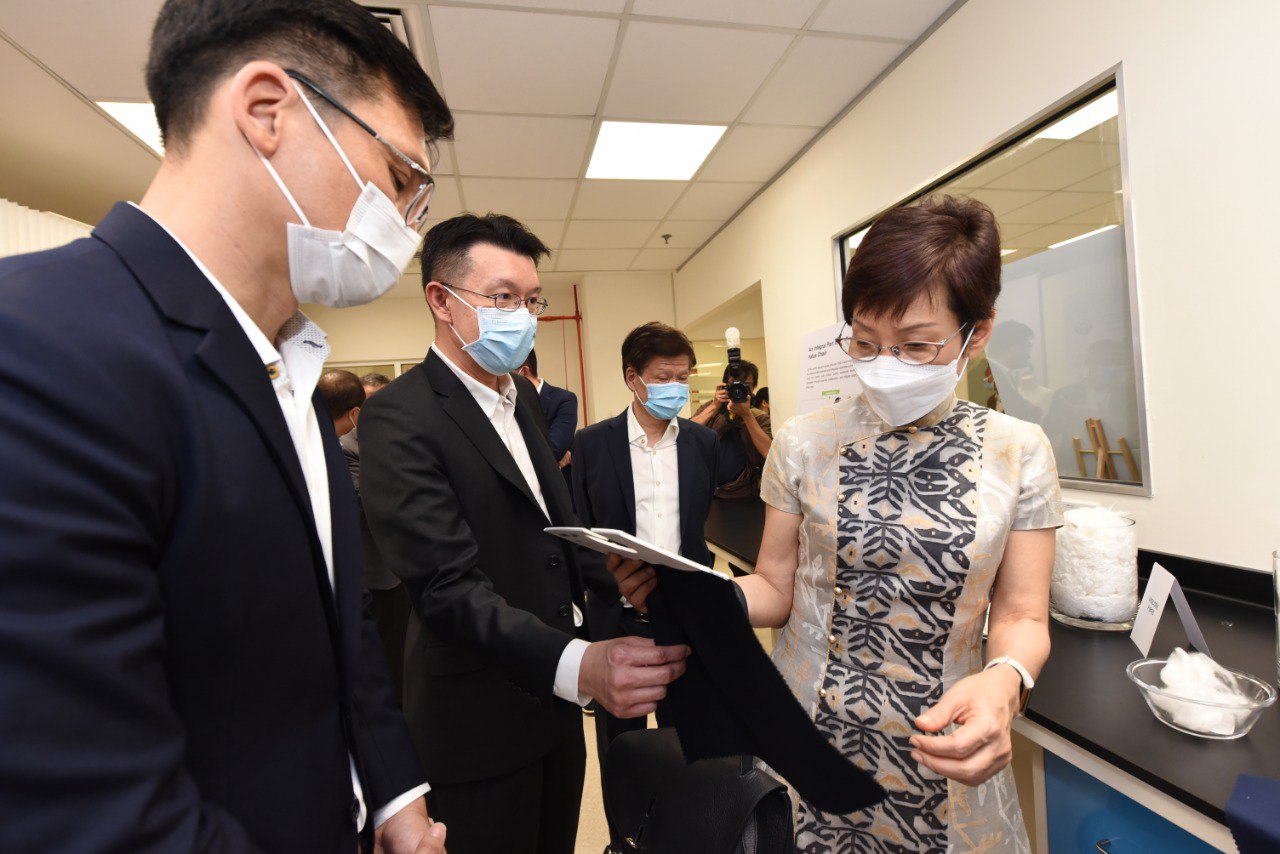

Minister Grace Fu touring RGE-NTU SusTex laboratory along with RGE Vice Chairman, Mr Bey Soo Khiang, RGE Executive Director, Mr Perry Lim, RGE Managing Director, Mr Anderson Tanoto, and RGE President. Mr Tey Wei Lin

“Together with NTU, we aim to catalyse innovation and develop research outcomes that can address these issues in textile waste recycling. We also aim to establish an urban-fit pilot textile recycling plant in Singapore that uses less energy, fewer chemicals and produces harmless and a lesser level of effluents. We believe that a textile recycling plant in an urban locality, that produces recycled pulp and other processed recycled materials that can be exported, will be a compelling proposition.”

Minister Grace Fu touring RGE-NTU SusTex laboratory along with RGE Vice Chairman, Mr Bey Soo Khiang, RGE Executive Director, Mr Perry Lim, RGE Managing Director, Mr Anderson Tanoto, and RGE President. Mr Tey Wei Lin

The research centre reflects RGE’s commitment to promote the circularity of textiles, in line with Singapore’s Zero Waste vision and the Sustainable Living pillar of the Singapore Green Plan 2030.

Guest-of-Honour for the event, Ms Grace Fu, Singapore Minister for Sustainability and the Environment, described the RGE-NTU SusTex as a “timely” initiative. She said, “The Centre’s research into cleaner and more efficient means of mixed fibre separation, new functional materials, and environmentally-friendly processes of dye removal and natural dyes development, will help the textile and fashion industry shift towards resource circularity and more sustainable means of production and recycling. I am hopeful that the research outcomes will contribute towards Singapore’s vision of becoming a Zero Waste Nation.”

NTU President, Prof Subra Suresh, highlighted that the partnership between NTU and RGE draws on RGE’s industry experience as the world’s largest producer of viscose fibre, and leverages NTU’s strong intellectual assets in material science and environmental chemistry.

RGE President Tey Wei Lin (centre) and RGE Executive Director Perry Lim (left) holding up a viscose fabric sample for Minister Grace Fu as she toured the RGE-NTU SusTex laboratory

Advancing Singapore’s sustainable development with fashion circularity

Led by two co-directors, Head of RGE Corporate Lab in Kerinci, Dr Jaroslav Stavik, and NTU Professor Hu Xiao, RGE-NTU SusTex will draw upon the expertise of NTU scientists in the School of Materials Science and Engineering and the School of Chemical and Biomedical Engineering. It will focus on four research programmes to develop:

To tackle the sizeable amounts of textile waste generated in urban cities, results from the first three research programmes will be used to build a textile recycling plant in Singapore that is capable of converting local textile waste into raw material for use in, or export from, the city-state.

The pilot plant will be established in stages, in tandem with the technologies that the research centre will develop. RGE is exploring potential collaboration with the armed services, restructured hospitals and hotels to recycle their textile waste that are of known composition.

The fourth research programme is where the RGE-NTU research collaboration can find synergy with RGE’s strategic partnership with the Singapore Textile and Fashion Federation (TaFF) to advocate sustainable industry practices within Singapore and the region. Tapping into the network of TaFF, RGE aims to promote the use of sustainable materials developed by the research centre in the mainstream textile and fashion industry.

RGE also hopes to leverage the research findings and technology, and potentially apply them at scale across its global operations.

RGE’s five-year research partnership with NTU (REG-NTU SusTex) and its three-year partnership with TaFF form part of its US$200 million commitment into next-generation textile fibre innovation and technology, as announced in 2019.

Operating at the heart of the bioeconomy, with sustainability at its core, RGE aims to make a meaningful contribution to support Singapore’s desire to advance sustainable development and create a green economy.

[1] The impact of textile production and waste on the environment, European Parliament News, 26 Apr 2022