Making a Social Impact: Crossing the Chasm

A solid marketing and branding strategy to help migrant workers in Singapore improve their command of English – that was Team iChange’s grand prize-winning proposal at the inaugural “Crossing the...

Latest updates on what's happening in RGE Group

Pacific Oil & Gas (PO&G) is an independent energy resources development company focused on helping meet the increasing energy requirements of growing Asian economies. Formed in 2003, it invests, develops, builds, owns, and operates innovative projects throughout the energy supply chain. In this series ‘Aiding Asia’s Clean Energy Transition’, we take a peek at some of its operating assets in Canada.

Pacific Canbriam Energy Limited (PCE) is a leading exploration and production company focused on finding and developing over-pressured, liquid rich natural gas resources in the Western Canadian Sedimentary Basin.

PCE will supply PO&G’s proposed Woodfibre LNG project.

PCE’s current total processing capacity is 210 million cubic feet per day, which represents approximately 40,000 barrels of oil equivalent when factoring in the liquids component of our production stream.

In 2015, the company added the first two phases of the Altares Processing Facility, located at b-72-A, adding an additional 160 million cubic feet per day of processing capacity. The design of this facility allows for two more phases of expansion, allowing for an additional 240 million cubic feet per day of processing capacity when fully built out. The ultimate designed capacity of the facility is 400 million cubic feet per day.

As of now, construction has commenced and long lead-time equipment has been ordered for the third phase of the Altares Processing Facility which will add an additional 120 million cubic feet per day.

Water is a critical part of the natural gas extraction process. After a well has been drilled, a mixture of mostly water and a small amount of additives is injected at high pressure to create cracks in the rock so the gas can escape.

PCE has enacted a three-part water strategy that involves sourcing, recycling, and effective disposal. This innovative approach to water ensures that we are carefully managing our critical fresh water resources in a responsible way. This approach also ensures that our long-term development is supported with sufficient water requirements.

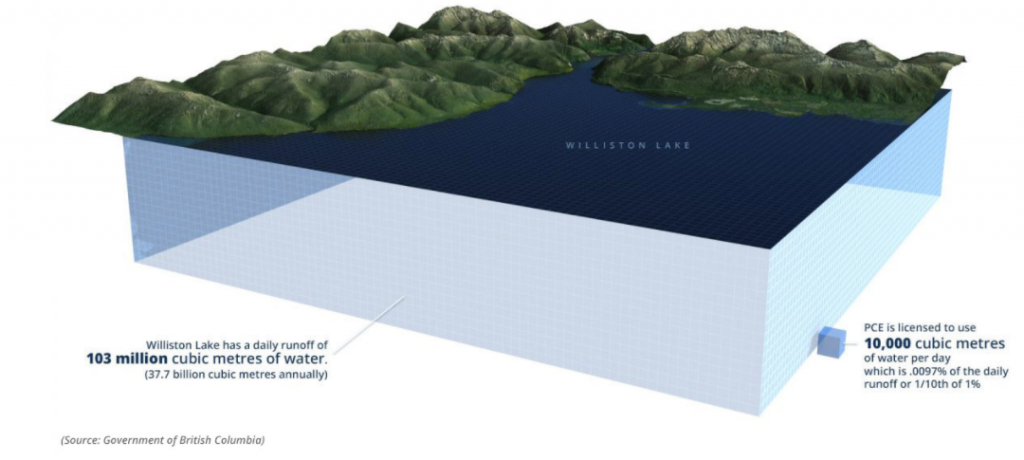

Our approach to water use is industry-leading. We source water from the man-made Williston Lake Reservoir, and pipe it to our facilities – eliminating the need for trucks. Most significantly, PCE has invested in a water recycling hub that allows us to re-use up to 99 per cent of our produced water. This water strategy is designed to support development up to 1 Bcf/d of production.

Once new wells are brought online, all water is transferred by pipeline to the water handling facility, where it is treated and stored for future use. This closed system supports the efficient handling and distribution of water. Any waste water is disposed through a series of disposal wells, which are continuously monitored by our passive seismic monitoring array. PCE has eliminated any trucking of water, which is good for business and good for the environment.

Drilling

First, the well is drilled vertically. Unconventional natural gas reserves are typically found two to three kilometres below the earth’s surface, hundreds of metres deeper than drinkable groundwater. Once the vertical well reaches the target formation, the well is turned to drill horizontally through the formation. Horizontal drilling can extend through the resource-bearing formation for a kilometre or more.

Surface Casing

Near-surface layers including soil and groundwater are protected by steel casing and cement that create a solid barrier between the well and underground water sources. Intermediate casing extends even deeper below any fresh water sources and provides an additional protective layer

Perforating the Wellbore

Prior to fracturing, the wellbore casing is perforated so fracturing fluid can be forced out of the wellbore and into the rock formation, and so oil or natural gas can flow into the wellbore and be brought to the surface. Perforating causes initial cracks in the formation that are extended during the fracturing process.

Fracturing

Fluid comprised of water, sand and a small volume of additives is pumped down the well under high pressure that further fractures the rock after perforation. These fractures extend between 50 and 100 metres from the horizontal wellbore. The sand holds the fractures open to provide pathways for natural gas to flow into the wellbore for extraction. A well is typically fractured once and may produce for up to 20 to 30 years.

Canada is among the world’s most socially and environmentally responsible producers of natural gas. There are rigorous legal, environmental, and social guidelines that govern the safe production and distribution of natural gas in Canada.

Northeastern British Columbia is home to abundant reserves of natural gas that are located in deep underground rock formations.

Technological advancements in hydraulic fracturing has safely unlocked abundant natural gas resources that have improved the quality of life for millions of people around the world. Natural gas provides a significant amount of energy with far lower emissions than other fossil fuels. Clean burning natural gas is a plentiful and inexpensive source of energy that heats our homes, helps cook our food, and generates our electricity.

Natural gas is a vital component of today and tomorrow’s clean energy mix.

Produce Positive Energy Together with Pacific Canbriam Energy!

More on PO&G: